Overview:

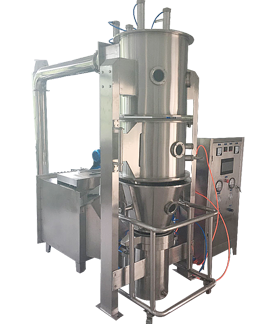

Boiling drying, also known as fluidized bed, it is by the air filter, heater, boiling bed host, cyclone separator, bag filter, high pressure centrifugal fan, console composition, due to the different nature of dry materials, matching dust removal equipment , May need to consider, can also select the cyclone, bag filter, can also choose one, generally speaking, such as a larger proportion of granules and dry granulation materials simply select the cyclone, the proportion of lighter particles Shaped and powdery materials to be equipped with bag filter, and equipped with pneumatic feeding device and belt conveyor for selection.

The particulate solid material is fed into a fluidized bed dryer by a feeder. The filtered clean air is heated and then sent to the bottom of the fluidized bed by a blower to contact the solid material through a distribution plate to form a fluidized and heat-mass exchange. After the material is dried, it is discharged from the discharge port, and the exhaust gas is discharged from the top of the ebullating bed and is evacuated by the cyclone dust collector and the bag filter to recover the solid powder.

Steam, electricity, hot stove can be equipped with (according to user requirements matching).

It is suitable for the drying of bulk materials, such as the drying and dehumidification of pharmaceutical raw materials, tablet granules, Chinese medicine granules, plastic resins, citric acid and other powdery and granular materials in chemical raw materials, Food and beverage granules, food processing, corn germ, feed, such as d

Features:

Fluidized bed dryer can be automated production, is a continuous drying equipment. Drying speed, low temperature, to ensure product quality, in line with drug production GMP requirements, steam, electricity, hot stove can be equipped with.

| 技术参数 \型号规格 | XF0.25 -1(原XF10) | XF0.25 -2(原XF20) | XF0.25 -3(原XF30) | XF0.25 -6 | XF0.3 -2 | XF0.3 -4 | XF0.3 -6 | XF0.3 -8 | XF0.3 -10 | XF0.4 -4 | XF0.4 -6 |

| 床层面积(m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 |

| 干燥能力 (kg h2O/h) | 10~15 | 20~25 | 30~45 | 52~75 | ~30 | 42~60 | 63~90 | 84~120 | 105~150 | 56~80 | 84~120 |

| 风机功率(kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 |

| 进风温度 (℃) | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 |

| 物料温度 (℃) | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 |

| 外形尺寸 (主机) 长×宽×高 | 1 ×0.6 ×3.35 | 2 ×0.6 ×3.35 | 4 ×0.6 ×3.35 | 6 ×0.6 ×3.35 | 2 ×0.7 ×3.4 | 4 ×0.7 ×3.4 | 6 ×0.7 ×3.4 | 8 ×0.7 ×3.4 | 10 ×0.7 ×3.4 | 4 ×1 ×3.58 | 6 ×1 ×3.58 |

| 占地面积 (m2) | 18 | 25 | 35 | 40 | 25 | 38 | 45 | 56 | 70 | 18 | 56 |

| 技术参数 \型号规格 | XF0.4-8 | XF0.4-10 | XF0.4-12 | XF0.5-4(原XF60) | XF0.5-6 | XF0.5-8 | XF0.5-10 | XF0.5-12 | XF0.5-14 | XF0.5-16 | XF0.5-18 |

| 床层面积(m2) | 3.2 | 4.0 | 4.8 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 |

| 干燥能力 (kg h2O/h) | 112~160 | 140~200 | 168~240 | 70~100 | 105~150 | 140~200 | 175~250 | 210~300 | 245~350 | 280~400 | 315~450 |

| 风机功率(kw) | 48 | 70 | 70 | 30 | 48 | 70 | 105 | 140 | 147 | 169 | 197 |

| 进风温度 (℃) | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 | 120~140 |

| 物料温度 (℃) | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 |

| 外形尺寸 (主机) 长×宽×高 | 8×1×3.58 | 8×1×3.58 | 12×1×3.58 | 4×1.2×4.1 | 6×1.2×4.1 | 8×1.2×4.1 | 10×1.2×4.1 | 12×1.2×4.1 | 14×1.2×4.1 | 16×1.2×4.1 | 18×1.2×4.1 |

| 占地面积 (m2) | 74 | 82 | 96 | 50 | 70 | 82 | 100 | 140 | 180 | 225 | 268 |