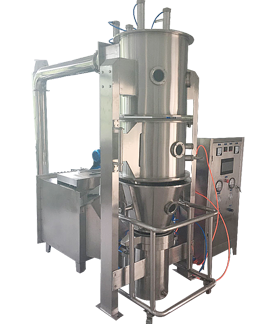

Overview:

ZLG vibrating fluidized bed dryer is widely used in the drying, cooling and humidifying of powdered granular materials in chemical, light industry, medicine, food, plastic, grain, oil, slag, salt and sugar industries.

principle:

Material from the feed inlet into the machine, the vibration force, the material along the horizontal direction of the continuous throwing forward movement, hot air upward through the fluidized bed with the wet material heat exchanger, the wet air through the cyclone dust removal by the exhaust Mouth discharge, dry material discharged from the discharge port.

Features:

● vibration source is the use of vibration motor drive, smooth operation, easy maintenance, low noise, long life, easy maintenance.

● high thermal efficiency, than the average drying device can save more than 30%. Bed temperature uniformity, no local overheating phenomenon, fluidized symmetry, no dead angle phenomenon.

● Adjustability is good, adapt to the surface width. Material thickness and the moving speed in the machine and the whole amplitude can be changed evenly stepless adjustment.

● The material surface damage is small, can be used for fragile material drying; irregular particles of material does not affect the work results.

● Fully enclosed structure, effectively preventing the material and the air between the air fork infection operating environment clean.

● When used for mass production of high-moisture materials, multiple series can be used to meet user requirements (typical materials: such as polyacrylamide, etc.).

技术参数表:

机型 | 流化床面积 m2 | 进风温度 ℃ | 出风温度 ℃ | 蒸发水份能力 Kg/h | 振动电机 | |

型号 | 功率KW | |||||

ZLG3×0.30 | 0.9 | 70~140 | 40~70 | 20~35 | YZS8-6 | 0.75×2 |

ZLG4.5×0.30 | 1.35 | 35~50 | YZS10-6 | 0.75×2 | ||

ZLG4.5×0.45 | 2.025 | 50~70 | YZS15-6 | 1.1×2 | ||

ZLG4.5×0.60 | 2.7 | 70~90 | YZS15-6 | 1.1×2 | ||

ZLG6×0.45 | 2.7 | 80~100 | YZS15-6 | 1.1×2 | ||

ZLG6×0.60 | 3.6 | 100~130 | YZS20-6 | 1.5×2 | ||

ZLG6×0.75 | 4.5 | 120~170 | YZS20-6 | 1.5×2 | ||

ZLG6×0.9 | 5.4 | 140~170 | YZS30-6 | 2.2×2 | ||

ZLG7.5×0.6 | 4.5 | 130~150 | YZS30-6 | 2.2×2 | ||

ZLG7.5×0.75 | 5.625 | 150~180 | YZS40-6 | 3.0×2 | ||

ZLG7.5×0.9 | 6.75 | 160~210 | YZS40-6 | 3.0×2 | ||

ZLG7.5×1.2 | 9.0 | 200~280 | YZS50-6 | 3.7×2 | ||

ZLG7.5×1.5 | 11.25 | 230~330 | YZS50-6 | 3.7×2 | ||

ZLG8×1.8 | 14.4 | 290~420 | YZS75-6 | 5.5×2 | ||