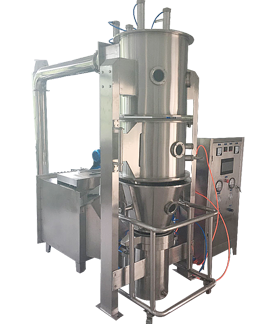

Overview:

XSG series rotary flash dryer is our factory in the introduction, absorption of foreign advanced technology, based on the successful development of new drying equipment. The machine has advanced technology, reasonable design, compact structure, wide application scope, large production capacity, good product quality, high efficiency and energy saving. It can dry, grind and sieve in one equipment in one time to eliminate environmental pollution. International advanced technology level.

principle:

Hot air from the inlet pipe at the appropriate speed from the bottom of the dryer into the mixing crushing chamber, the material produces a strong shear, blowing floating, rotating role, so the material subject to centrifugation, shear, collision, friction and is divided by the number of micronization , Enhanced heat and mass transfer. At the bottom of the dryer, the larger, wetter particles are mechanically broken by the agitator. The particles with low moisture content are entrained by the rotating airflow and are further dried during the rising process. Because the gas-solid two-phase rotation flow, solid-phase inertia is larger than the gas phase, solid-gas two-phase relative velocity is bigger, strengthen two-phase mass transfer heat transfer, so the machine production intensity is high.

Features:

● A variety of feeding device for choice, feeding continuous and stable, the middle of the process does not produce bridging phenomenon.

● The bottom of the dryer to set a special cooling device to avoid the material at the bottom of the phenomenon of high-temperature metamorphism.

● Special air seal and bearing cooling device, effectively extending the service life of the transmission part.

● The special air distribution device reduces the resistance of the equipment and effectively provides the air volume of the dryer.

● Drying chamber is equipped with grading ring and swirl piece, material fineness and final moisture can be adjusted. (Such as calcium carbonate final moisture regulator to ≤ 0.1%)

● Compared with other drying methods, can effectively increase the proportion of materials.

● Drying chamber with high gas velocity in the circumferential direction, short material stay time, effectively preventing the material sticky wall and heat-sensitive materials from degeneration, to achieve high efficiency, fast, small equipment and large-scale production.

● inorganic: boric acid, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony trioxide, all kinds of metal hydroxides, all kinds of heavy metal salts, synthetic cryolite.

● organic matter: atrazine (pesticide pesticides), lauric acid separated, benzoic acid, benzoic acid, bactericidal Dan, sodium oxalate, cellulose acetate.

● Ceramics: kaolin, silica, clay.

Dyes: anthraquinone, black iron oxide, indigo pigments, butyric acid, titanium hydroxide, zinc sulfide, various azo dyes intermediates.

● food categories: soy protein, gelatinized starch, lees, wheat sugar, wheat starch.

Technical Data Sheet:

| 型号 | 主机内经(mm) | 处理风量(m3/h) | 蒸发水量(kg/h) | 最大装机容量(KW) | 最大高度(m) | 占用平面(m2) |

| XSG-4 | 400 | 1150-2300 | 58-73 | 21.4 | 4.6 | 27 |

| XSG-6 | 600 | 2500-5100 | 130-163 | 34.2 | 5.5 | 39 |

| XSG-8 | 800 | 4500-9000 | 238-297 | 63.5 | 6.0 | 40 |

| XSG-10 | 1000 | 7000-13500 | 345-430 | 68 | 6.5 | 55 |

| XSG-12 | 1200 | 10000-20000 | 515-645 | 94 | 6.8 | 62 |

| XSG-14 | 1400 | 16600-28000 | 730-910 | 130 | 7.0 | 89 |

| XSG-16 | 1600 | 18000-38100 | 962-1203 | 160 | 7.2 | 160 |

Note: 1. Moisture evaporation is based on the inlet temperature of 200 ℃, the wind 80 ℃ Total 2, installed capacity as the basic data, according to material properties change. 3, the area according to the actual layout, the data in the table is for reference only.