principle:

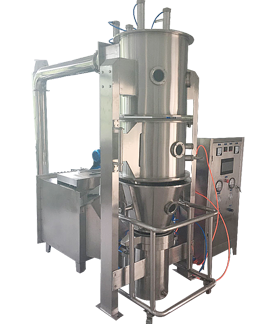

QG series of pulsed air dryer is a large batch of drying equipment, which uses the principle of instant drying, the use of hot air carrying the rapid movement of wet materials, wet materials suspended in hot air, thus strengthening the entire drying process , Improve the heat and mass transfer rate, through the air drying material, non-combined moisture can be almost completely removed, and the dry material, will not produce metamorphism, the output can be significantly higher than the general dryer drying, the user can short- To achieve a higher economic efficiency.

Adapt to the material:

This type of equipment to adapt to the material more, in addition to the basic type of materials mentioned, there are: sleeping ketone, A. B. C intermediate, A. B. S resin, . C, white carbon black, benzophenone pyrazolone, tea meal, oxalic acid catalyst, accelerator m. D. M, catalyst, precipitated charcoal powder, p-acetyl nitrobenzene sulfonamide, p-aminosalicylic acid, duo Mate, terephthalic acid, diethyl aniline, titanium dioxide, activated carbon, sodium fluorosilicate Calcium silicate powder, synthetic resin, calcium phosphate, polypropylene resin, chlortetracycline, sodium pyrophosphate, bran chloric acid, tetracycline, ferric oxide, calcium carbonate, corn protein, iron oxide, gypsum retarder.

Key recommendation: for wood flour, wood chips, rice bran, bran dry

The above-mentioned materials have particularity: light weight, difficult to feed, flammable, explosive. In response to this situation, our technology sector developed a new air dryer, in the original air dryer on the basis of improving the feeding form, to solve the "bridge" phenomenon. Innovation improved the cyclone separator, to solve the phenomenon of material rolling is not expected. System integration, advanced control, over-temperature alarm off the chain of heat, an effective solution to the high temperature caused by combustion and explosion problems.

Technical Data Sheet:

| 型号 | 蒸发水份 kg/h | 装机功率 kw | 占地面积 m2 | 高度 m | | QG50 | 50 | 7 | 20 | 14 | | QG100 | 100 | 13 | 32 | 14 | | QG200* | 200 | 21 | 40 | 15 | | QG250 | 250 | 24 | 64 | 15 | | QG500 | 500 | 43 | 96 | 18 | | QG1000* | 1000 | 100 | 120 | 18 | | QG1500* | 1500 | 150 | 200 | 20 |

Note: part of the design parameters, depending on the material has been adjusted to design prevail. |