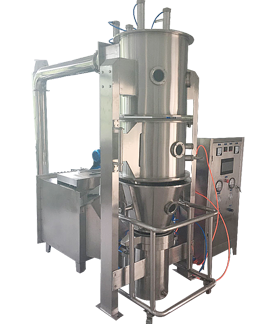

Roller scraper dryer is an internal heating conduction continuous rotary drying equipment. The rotating drum passes through its lower chute and adheres to a thick material film. The heat is transferred to the inner wall of the drum through the pipe and is transmitted to the outer wall of the drum, and then the feed film is transferred to evaporate and dehumidify the moisture in the film. The moisture-containing material is dried. Dry material is installed in the roller surface of the scraper from the drum, to the scraper below the screw conveyor, through the screw conveyor to dry material concentration, packaging.

Features:

● High thermal efficiency. Because of the heat transfer mechanism of the drum dryer is a heat transfer, heat transfer direction in the entire operating cycle to maintain the same, in addition to cover the heat dissipation and heat loss, the rest of the heat are used for evaporation of the film material moisture, the thermal efficiency of up to 80% -90%.

● Operation flexibility, wide applicability. Various drying factors of the drum dryer can be adjusted. Such as the concentration of feed, the thickness of the coating film, the heating medium temperature, drum rotation speed, etc., can change the drying efficiency of the drum dryer, and many factors are not involved. This gives the drum drying operation a great convenience, so that it can adapt to a variety of dry materials and different production requirements.

● Drying time is short. Drying period of the material is generally only 10-300 seconds, suitable for heat-sensitive materials. If the drum dryer is set in a vacuum, it can be operated under reduced pressure.

● Drying rate is high. As the coating material on the tube wall thin film, generally 0.3-1.5mm, and the heat transfer, mass transfer in the same direction, the membrane surface can maintain 20-70kg • H2O / m2 • h evaporation.

application:

HG series of roller scraper dryer is widely used in food, chemical, pharmaceutical and other industries sticky, paste paste material production, drying and other processes.

Technical Data Sheet:

规格 | 滚筒尺寸(mm) | 有效加热面积(m2) | 干燥能力(kg/h) | 蒸汽耗量(kg/h) | 电机功率(kw) | 外形尺寸(mm) | 重量(kg) |

HG-600 | Φ600×800 | 1.12 | 40-70 | 100-175 | 1.1 | 1700×800×1500 | 850 |

HG-700 | Φ700×1000 | 1.65 | 60-90 | 150-225 | 2.05 | 2100×1000×1800 | 1210 |

HG-800 | Φ800×1200 | 2.26 | 90-130 | 225-325 | 3.75 | 2500×1100×1980 | 1700 |

HG-1000 | Φ1000×1400 | 3.30 | 130-190 | 325-475 | 4.75 | 2700×1300×2250 | 2100 |

HG-1200 | Φ1200×1500 | 4.24 | 160-250 | 400-625 | 4.75 | 2800×1500×2450 | 2650 |

HG-1400 | Φ1400×1600 | 5.28 | 210-310 | 525-775 | 6.25 | 3150×1700×2800 | 3220 |

HG-1600 | Φ1600×1800 | 6.79 | 270-400 | 675-1000 | 6.25 | 3350×1900×3150 | 4350 |

HG-1800 | Φ1800×2000 | 8.48 | 330-500 | 825-1250 | 8.6 | 3600×2050×3500 | 5100 |

HG-1800A | Φ1800×2000 | 10.60 | 420-630 | 1050-1575 | 8.6 | 4100×2050×3500 | 6150 |

Note: part of the design parameters, depending on the material has been adjusted to design prevail.