Overview:

DWT dehydration dryer is a special type equipment researched and developed on the basis of the traditional net belt type dryer. It has strong pertinence, practicability and high energy efficiency. It is widely used in the dehydration of various regional and seasonal vegetables and fruits. Dry, such as: Suanpian, pumpkin, konjac, white radish, yam, bamboo shoots, etc., has more than 50 users, more than 80 sets of online equipment, is the most experienced vegetable drying equipment manufacturers, factory science and technology personnel long-term tracking Service to these users, in-depth user debugging research, get first-hand practice of information and advanced technology with foreign advanced equipment to improve and perfect, so far, has developed a third generation DWT series of vegetables dehydration dryer, Production equipment, according to the characteristics of the required drying products, the user process requirements, combined with more than 10 years of accumulated experience for the user to design and produce the most applicable, the best quality of the vegetable drying equipment.

application:

Can meet the root, stem, leaf-like strip, block, flakes, large particles and other vegetable materials, dry and large quantities of continuous production, while the maximum retention of product nutritional content and color.

Dried typical materials are: garlic pieces, pumpkin, carrots, konjac, yam, bamboo shoots, horseradish, onions, apples and so on.

Features:

Drying area, wind pressure, air flow, drying temperature, mesh belt speed can be adjusted to meet the characteristics of vegetables and quality requirements.

According to the different characteristics of vegetables, using different water processes and supporting the necessary auxiliary equipment.

principle:

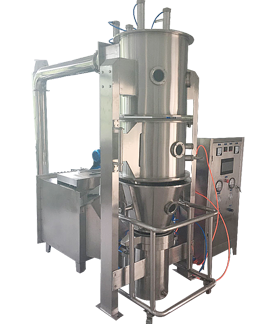

Vegetable dehydration dryer, respectively, with feeder, drying bed, heat exchangers and moisture exhaust fan and other major components.

Dryer work, the cold air through the heat exchanger to heat the use of scientific and rational recycling, so that hot air through the bed through the drying of the material to be a uniform heat and mass exchange, the body of each unit in the role of hot air circulating fan Under the hot air circulation, the final discharge of low temperature and high humidity air, smooth and efficient completion of the entire drying process.

技术参数表:

| 型号 | DWT1.6-Ⅰ (加料台) | DWT1.6-Ⅱ (中间台) | DWT1.6-Ⅲ (出料台) | DWT2-Ⅰ (加料台) | DWT2-Ⅱ (中间台) | DWT2-Ⅲ (出料台) |

| 网带宽m | 1.6 | 1.6 | 1.6 | 2 | 2 | 2 |

| 干燥段长m | 10 | 10 | 8 | 10 | 10 | 8 |

| 铺料厚度mm | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

| 使用温度℃ | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ |

| 换热面积m2 | 525 | 398 | 262.5 | 656 | 497 | 327.5 |

| 蒸汽压力 Mpa | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 |

| 干燥时间h | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 |

| 装机功率KW | 15.75 | 12.75 | 9.55 | 20.75 | 16.75 | 12.55 |

| 外形尺寸m | 12×1.81×1.9 | 12×1.81×1.9 | 10×1.81×1.9 | 12×2.4×1.92 | 12×2.4×1.92 | 10×2.4×1.92 |

Note: 1, the table will be a unified specification of the network with dryer dryer units, the middle Taiwan, the three sets of materials used in series to ensure that the dehydration of vegetables drying production process requirements, significantly improve production and effective guarantee of product quality.

2, equipment height does not include the fan, duct height.

3、部分参数设计时视不同物料有所调整,以设计为准