Product details: | |

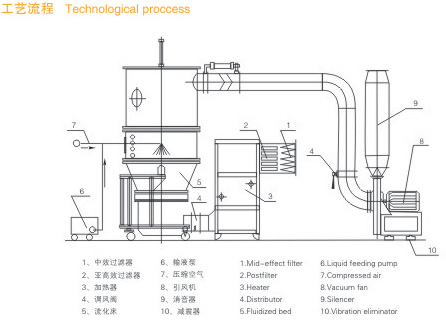

application: ● granulation in the pharmaceutical industry: tablet granules, granules granules, capsules particles. ● granulation of the food industry: cocoa, coffee, milk powder, granular fruit juice, spices and so on ● granulation in other industries: pesticides, feed, chemical fertilizers, pigments, dyes and chemicals. Drying of powdered or granular wet materials. ● Coating: granules, pills protective layer, prepared color, slow release, film, enteric coating and so on. working principle: The material powder particles are in an annular fluidized state in a raw material container (fluidized bed), preheated and mixed by the heated air after being purified, atomized and sprayed by the binder solution, and aggregated into particles containing binder Of the pellets, as the hot air drying of the material, so that water evaporation in the aggregate, the adhesive solidification, the process continues to repeat, the formation of the ideal, uniform multi-porous spherical particles. Features: ● through the powder granulation, improve mobility, reduce dust flying: ● improve its solubility by powder granulation; ● mixing, granulation, drying in a machine to complete one-step granulation; ● The use of antistatic filter cloth, equipment, safe operation; ● Set the pressure relief hole, in the event of an explosion, equipment personnel from harm; ● The equipment has no dead angle, the loading and unloading material is light and fast, rinsing cleanly, meeting the GMP standard. |

Technical Data Sheet:

项 目 | 单 位 | 机型 | |||||||||

3 | 5 | 15 | 30 | 60 | 120 | 200 | 300 | 500 | |||

原料容器 | 容量 | L | 12 | 22 | 45 | 100 | 220 | 420 | 670 | 1000 | 1500 |

直径 | mm | 300 | 400 | 550 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | |

生产能力 | 最小 | Kg | 1.5 | 4 | 10 | 15 | 30 | 80 | 100 | 150 | 250 |

最大 | Kg | 4.5 | 6 | 20 | 45 | 90 | 160 | 300 | 450 | 750 | |

风机 | 风量 | m3/h | 1000 | 1200 | 1400 | 1800 | 3000 | 4500 | 6000 | 7000 | 8000 |

风压 | mmH2O | 375 | 375 | 480 | 480 | 950 | 950 | 950 | 950 | 950 | |

功率 | Kw | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 | 30 | 45 | |

蒸汽消耗量 | Kg/h | 15 | 23 | 42 | 70 | 141 | 211 | 282 | 366 | 451 | |

压缩空气耗量 | m3/min | 0.9 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1.1 | 1.5 | 1.5 | |

主机 | Kg | 500 | 700 | 900 | 1000 | 1100 | 1300 | 1500 | 1800 | 2000 | |

蒸汽 | Mpa | 0.3~0.6 | |||||||||

温度 | ℃ | 室温-120℃范围内可调节 | |||||||||

作业 | min | 随物料特性而定45~90 | |||||||||

物料收得率 | ﹪ | ≥99 | |||||||||

噪声 | dB(A) | 风机与主机隔离安装,噪声≤75 dB(A) | |||||||||

主机外形尺寸L×W×H | m | 1.0×0.6 | 1.2×0.7 | 1.25×0.9 | 1.6×1.1 | 1.85×1.4 | 2.2×1.65 | 2.34×1.7 | 2.8×2.0 | 3×2.25 | |