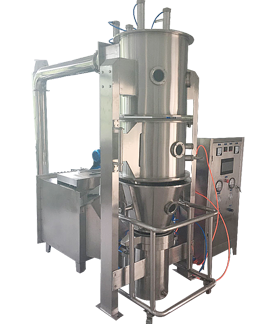

GFZL series of dry powder granulating machine is our company according to user needs, absorbing advanced foreign powder granulation technology on the basis of careful research and development of new granulation equipment, the device can be made directly to meet the user requirements powder raw materials granular Product, without adding any intermediates and additives, granulated product size uniformity, significantly increased the bulk density, at the same time, can effectively control pollution and reduce waste powder. Design science, compact structure, the process is simple, easy to operate, is your powder products, the ideal choice for granulation.

working principle:

Powder material by the vibration of the hopper by the horizontal screw feeder quantitative, even added to the main rolling hopper, the rolling of the main hopper to maintain a constant pellet, and then by rolling the main material of the longitudinal cone of the powder material Pre-compressed and transported to the two curved roller-notch roller, the two evenly distributed on the surface of the same shape semi-flat circular groove or diamond-shaped groove, through a pair of gear meshing drive, so that the two pressure roller constant speed , Reverse rotation, the cone screw conveyor to the slot material bite into the slot and instantly forced compression, the material after compression with the pressure gradually reduced in its elasticity and gravity under the action of shedding from the trough, into the broken whole System, and then according to the requirements of the user sieve size, grading, to be in line with the quality requirements of uniform granular products, sieve powder back to the vibration hopper recycling.

Features:

● without any additives, dry granulation direct.

● Particle strength can be adjusted by adjusting the pressure of the pressure roller to control the finished product strength.

● Cycle operation, to achieve continuous production.

● High yield of finished products, single machine output can reach more than 2000kg / h (bulk density 1.5 × 103kg / m3)

application:

Petrochemical

Biological Engineering

Metal powder

Fine Chemicals

Medicine

Food

Pesticides

Fertilizers

Minerals, coal

Technical Data Sheet:

型号/项目 | GFZL-1 | GFZL-2 | GFZL-3 | GFZL-4 | GFZL-5 |

轧辊直径mm | φ240 | φ240 | φ300 | φ360 | φ480 |

轧辊有效使用宽度mm | 80 | 160 | 250 | 360 | 480 |

轧辊转速rpm | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

最大成形压力t | 50 | 60 | 80 | 100 | 130 |

轧辊最大厚度mm | 4 | 5 | 6 | 8 | 8 |

轧片产量kg/h | 250-500 | 500-900 | 700-2000 | 1000-1400 | 2000-7400 |

成品粒度mm | 0.2-5 | 0.2-5 | 0.2-8 | 0.2-8 | 0.2-8 |

成品产量kg/h | 80-150 | 150-300 | 300-600 | 600-1000 | 1000-2000 |

主机功率kw | 7.5 | 11 | 15 | 22 | 30 |

总功率kw | 13 | 21 | 30 | 46 | 60 |

外形尺寸 长×宽×高mm | 1500×2000×3800 | 1700×2000×4000 | 2000×2500×4200 | 2500×2500×5200 | 2800×2600×6000 |

重量t | 7 | 8 | 10 | 14 | 20 |

Note: 1, the production of sheet density to 1500kg / m3, roller speed 20rpm calculation. 2, the finished product yield to the amount of 50% of the establishment. 3, the finished product size by changing the broken machine sieve plate aperture can be adjusted in a wide range. 4, the actual power used by the host for the selected motor power 70%. 5, roll speed by changing the motor and the reducer between the pulley drive to be adjusted. | |||||