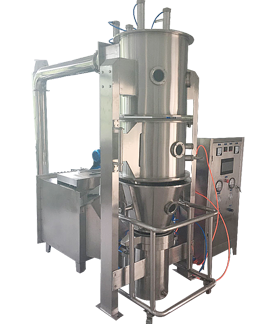

High speed centrifugal spray drying technology of series hot air circulation oven

Author: ComeFrom: Date:2017-01-03 14:07:40 Hits:1192

Spray drying is to disperse the solution into very fine droplets, so that in a short time (a few seconds) in the air to form a spherical powder. Spray drying is not only fast drying, hot air circulation oven can also provide a certain range of particle size of the powder products, can be cooling, granulation operation. The spray drying technology was identified, some technical indicators have been catch up with and surpass the advanced level of the century with the Danish company Nero (NiRO) index.

Scope of application of this technology:

Spray drying is widely used in medicine, food, ceramics and forest products, such as tannic acid, tannin, Gynostemma, animal glue, synthetic rubber, starch, dyes, cosmetics, animal and plant protein, milk powder, spices, natural pigment, yeast, sugar, enzyme, penicillin, streptomycin and so on. The application of technology in flue gas desulfurization in Baima power plant in Neijiang City, the desulfurization rate can reach more than 85%, won the first prize in the Department of energy science and technology progress by the State Planning Commission, the State Science and Technology Commission and the Ministry of Finance jointly issued the "national key scientific and technological achievement certificate".

Technical key and characteristics:

High speed centrifugal atomization technology: can be in the 1-3.5 million / min stable, long-term operation, due to the high speed, so: 1, shorten the nozzle distance, the smaller the diameter of the tower, reduce the cost of capital construction. 2, fine and uniform droplets, to ensure product quality. 3, compact tower, mass transfer, heat transfer efficiency is high.

Material: - high yield due to the unique cyclone separation technology in this system, when the pressure drop in the 150mm/ column below, the material recovery rate can reach 98% (cutting diameter of 20 microns), hot air circulation oven also available low pressure vertical Venturi cyclone scrubber, can second level recovery more than 99.99%.

- first "dimensional star valve": the device can make the drying tower, the lower part of the cyclone powder smoothly to the outside, to overcome the negative pressure in the discharge system caused by air leakage when the valve core jam and channeling wind etc..

Temperature feedback speed regulation: in the high viscosity material feeding, the use of a single screw pump, and the export temperature feedback speed regulation, to ensure that the final moisture content of the product to achieve constant.

New and unique "hose diaphragm pump": I have also developed a "hose diaphragm pump," which avoids the screw pump core and rubber sleeve friction. Due to the double isolation, the liquid can be absolutely pure and free from pollution.

- three fluid flow fountain mist technology: is suitable for high viscosity, high solids containing materials. This device was approved by the provincial level in 1984, and won the first prize.

Spray drying system complete specifications, can meet the requirements of different users, the amount of liquid spray can be from 0.5 kg / -10 kg / hour, a total of seven specifications for the user to choose.

Forms of foreign technical cooperation:

Design of drying device system 1 to undertake materials (including: single tower body, heating system, recovery system, operation steel platform, thermal and automatic control system).

2 special liquid material (such as: powder charged, high surface tension, high thermal, ultra-fine and so on), can provide consulting services or collaborative research.

Next:Nothing